- Afghanistan

- Africa

- Budget Management

- Defense

- Economy

- Education

- Energy

- Environment

- Global Diplomacy

- Health Care

- Homeland Security

- Immigration

- International Trade

- Iraq

- Judicial Nominations

- Middle East

- National Security

- Veterans

|

Home >

News & Policies >

February 2007

|

For Immediate Release

Office of the Press Secretary

February 22, 2007

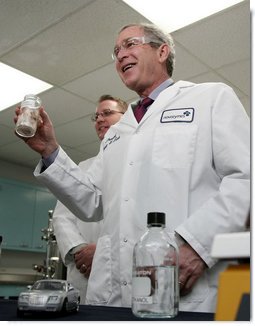

President Bush Participates in Panel on Cellulosic Ethanol

Novozymes North America, Inc.

Franklinton, North Carolina

![]() Fact Sheet: Harnessing the Power of Technology for a Secure Energy Future

Fact Sheet: Harnessing the Power of Technology for a Secure Energy Future

![]() In Focus: Energy

In Focus: Energy

12:10 P.M. EST

THE PRESIDENT: Thank you all very much. I like to tell people part of my job is to be the educator-in-chief. And today we're at a really interesting facility in North Carolina to talk about what's possible; what dreamers are doing to enable us to achieve a very important national goal, and that is to become less dependent on oil from overseas, thereby ensuring that our national security interests are better intact and our economic security interests are better intact and that we're better stewards of the environment. That's what we're here to talk about.

But before I do, I do want to thank some people. First, Laura sends her

regrets. I'm a lucky boy to have her -- (laughter) -- to have her as my

wife. We've got a lot of friends here in Carolina, and she sends her

best wishes to our Carolina friends. I told some folks yesterday, I'm

not very objective when it comes to my wife, but I think the country is

really lucky to have her as the First Lady. (Applause.)

But before I do, I do want to thank some people. First, Laura sends her

regrets. I'm a lucky boy to have her -- (laughter) -- to have her as my

wife. We've got a lot of friends here in Carolina, and she sends her

best wishes to our Carolina friends. I told some folks yesterday, I'm

not very objective when it comes to my wife, but I think the country is

really lucky to have her as the First Lady. (Applause.)

We're here at Novozymes, which is a company that makes enzymes. We're going to talk to Thomas, who is the President and Plant Manager, about what they do here, and why it's relevant. Before we get there, I do want to say something about Steen Riisgaard. He's the President and CEO, Steen. He flew over from Denmark. I can't thank you enough for coming. I appreciate you being here. It's interesting, isn't it, when you're able to sit in North Carolina and talk about a Danish company that is investing to not only help us become less dependent on oil, but equally importantly is investing capital, which enables citizens from the United States to find good work.

I toured around the facility, and I asked people at the facility how long they had been working here. And a lot of people have been here 20-plus years. So for those people who are worried about free trade, I want you to remember that if this country were to wall ourselves off from the world, we would miss opportunities to find markets for our products, and at the same time miss opportunities for citizens who work at a facility like this to find good work. It's in our interests that we have free and fair trade.

And so I thank you very much, Steen, for investing in the United States of America, and I appreciate the fact that you're sensitive to the needs of the workers here in the United States of America. And I see you're sitting next to your Ambassador. Mr. Ambassador, welcome. I'm glad you're here. (Applause.)

A person who understands the vast potential in the lands here in North Carolina to make us less dependent on oil is Richard Burr. He's the United States Senator. I'm proud he's joined us today, and thank you for coming, Senator. There you go. (Applause.) Congressman G.K. Butterfield. Thank you for being here, G.K. Appreciate you coming. (Applause.) He's a United States Congressman from the neighboring district, but he has enough interest in making sure that we succeed in alternative sources of energy, that he's here. He's also on an important subcommittee in the House. I appreciate your interest. Appreciate you joining us.

I want to thank the Agricultural Commissioner from the great state of

North Carolina, Steve Troxler, who's joined us today. Steve, thank you

for coming. There he is, right there. (Applause.) See, Steve needs to

take an interest in this like he is, because doesn't it make sense to be

able to say to our farmers, grow what you can grow so we become less

dependent on oil. I like the idea of a President being able to say,

wow, the crop report is in, we're growing more corn than ever before,

which means we're importing less oil from overseas. It's an exciting

time to think about that our farmers not only are going to grow what we

need to eat, but it's going to grow what we need to run our automobiles.

I want to thank the Agricultural Commissioner from the great state of

North Carolina, Steve Troxler, who's joined us today. Steve, thank you

for coming. There he is, right there. (Applause.) See, Steve needs to

take an interest in this like he is, because doesn't it make sense to be

able to say to our farmers, grow what you can grow so we become less

dependent on oil. I like the idea of a President being able to say,

wow, the crop report is in, we're growing more corn than ever before,

which means we're importing less oil from overseas. It's an exciting

time to think about that our farmers not only are going to grow what we

need to eat, but it's going to grow what we need to run our automobiles.

And that's coming. That's what we're here to discuss today. I know it sounds like a pipe dream to some -- you know, there goes the optimistic President talking again. But you're going to hear from some experts here. I'm just a history major. (Laughter.) And I'm with Ph.D.s. (Laughter.) Let me remind you who the President is. (Laughter and applause.)

But the Ph.D.s are providing the brain power necessary to help plants like this develop technologies that will enable us to convert wood chips into fuels that are running automobiles. It's an interesting time, isn't it, when you're able to say, we're on the verge of some breakthroughs that will enable a pile of wood chips to become the raw materials for fuels that will run your car.

I appreciate the Mayor, Jenny Edwards, here, Mayor of Franklinton, for joining us. Where are you, Madam Mayor? Thanks for coming. Proud to see you again. (Applause.) And all the Novozymes employees, I appreciate you setting this deal up and I appreciate you putting up with the hundreds who travel with me. (Laughter.) And thank you for your warm hospitality.

Look, here's -- I just told you the goal. The goal is for the United States to be -- to diversify away from old, old ways. And it's possible. And I do believe it is a proper use of your money, taxpayers' money, to spend to encourage research on interesting ideas. We spent about $12 billion since I've been your President to try to stimulate technologies that will literally change the way we live. A lot of that money has gone into clean coal technologies. If you're worried about dependency on oil from overseas, then it seems to make sense to me that we ought to be able to have the technology so that we can better use the resources we have here at home.

I don't know if you know this, we've got about 250 years worth of coal

in America. That's what they estimate. And it makes sense, therefore,

to spend money at the federal level to develop technologies so we can

burn that coal in environmentally friendly ways. The idea is to have

zero emission coal-fired plants here in America. And it's possible, and

we're making progress toward that goal.

I don't know if you know this, we've got about 250 years worth of coal

in America. That's what they estimate. And it makes sense, therefore,

to spend money at the federal level to develop technologies so we can

burn that coal in environmentally friendly ways. The idea is to have

zero emission coal-fired plants here in America. And it's possible, and

we're making progress toward that goal.

I happen to believe that if you're concerned about the environment and want to deal with renewable sources of energy, that we need to pursue nuclear power. Those power plants emit zero greenhouse gases. It doesn't require any hydrocarbons from overseas to run those plants. So we're beginning to license new plants. We're spending money on wind and solar energies. It makes sense to be able to -- as the price of hydrocarbons goes up, it makes sense that there be alternative sources of energy coming to the market as quickly as possible.

So we're making pretty good progress. But if you really want to reduce the amount of oil that you consume, you got to reduce the amount of gasoline you use. In other words, if you say, we want to reduce our dependence on oil, what you really got to do is change gasoline usage in the United States. And there's a couple of exciting things that are taking place -- one is new battery technologies. We're spending money at the federal level -- and by the way, there's a lot of private sector money going into alternative sources of energy. And some day you're going to be able to get in your car, particularly if you're a big-city person, and drive 40 miles on a battery. It's coming. And by the way, the car doesn't have to look like a golf cart. (Laughter.) It could be a pickup truck. (Laughter.)

And that technology is around the corner. And if we're able to drive the first 40 miles, or, say, 20 miles, on gasoline [sic] there's a lot of big-city folks that will never have to use a drop of gasoline on a daily basis. They'll be driving via electricity. These are lithium-ion batteries, technology -- so when you hear that term, you just got to know there's a lot of folks and a lot of money aiming hard to get this to the market as quickly as possible. Why? Because we've set a goal for the United States to be less dependent on oil.

Secondly -- and this is what we're here to talk about today -- is

ethanol. It says that the new developments in ethanol -- in other

words, fuel derived from corn -- can be diversified. Here's the

problem: Right now we're consuming about 7 billion gallons of ethanol a

year made from corn. And it's a pretty standard process. People here

at this facility have developed the enzymes necessary to break the corn

down in an efficient way so that we can use ethanol derived from corn.

Secondly -- and this is what we're here to talk about today -- is

ethanol. It says that the new developments in ethanol -- in other

words, fuel derived from corn -- can be diversified. Here's the

problem: Right now we're consuming about 7 billion gallons of ethanol a

year made from corn. And it's a pretty standard process. People here

at this facility have developed the enzymes necessary to break the corn

down in an efficient way so that we can use ethanol derived from corn.

The problem is we got a lot of hog growers around the United States and a lot of them here in North Carolina who are beginning to feel the pinch as a result of high corn prices. A lot of the cattle people around the United States -- I have got a few of them in my home state of Texas -- they're worried about high corn prices affecting their making a livelihood. In other words, the demand for corn, because of agricultural use, and now energy use, is causing corn prices to go up. I bet you the Agriculture Commissioner is hearing from folks.

And so how do -- the question then is, how do you achieve your goal of less dependence on oil without breaking your farmers -- without breaking your hog raisers -- corn farmers happen to like it, but I'm talking about the -- (laughter) -- people dependent on corn.

And here's how: You develop new technologies that will enable you to make ethanol from wood chips, or stalk grass, or agricultural waste. And that's what we're here to talk about: Is it possible, and if it is possible, how close are we to achieving the technological breakthroughs that I believe are possible so that our -- so that we're changing our habits.

And these are exciting times, they really are. I've always said, America needs to stay on the leading edge of technological change. It will mean we remain a really important economy in the world, but it will also mean that our folks will be able to find good high-paying jobs.

In this case, being on the leading edge of technological change means that we'll also be able to deal simultaneous with economic insecurities that come when China demands more for oil, the world produces less, the price of oil goes up, and so does the price of gas at the pump here in North Carolina; national security concerns where some people who've got oil don't like us, and therefore, may be willing to use their energy resources to try to cause America to take a different view of the world; and environmental concerns. And all these three concerns come together with technology as the solution.

And so Thomas, tell people what you do. (Laughter and applause.)

And so Thomas, tell people what you do. (Laughter and applause.)

MR. NAGY: That was a -- that was a nice introduction. Thank you, Mr. President. You may know, and many of you here -- first of all, I want to welcome you very, very deep from my heart and from all my colleagues here in Franklinton, welcome to North Carolina, welcome to Novozymes, and also welcome to the guests here. (Applause.)

THE PRESIDENT: Well, thank you. Like you're the President, right?

MR. NAGY: Well, you're the President. (Laughter.) Okay, anyways --

THE PRESIDENT: It didn't take him long to learn, you know. (Laughter.)

MR. NAGY: Novozymes is the world's leading biotechnology company within the field of industrial enzymes and microorganisms. We market more than 600 products around the globe, and all of these products have the same in common, that they -- sort of like it's good for environment, it's good for businesses, because when using our products, you use less resources, less energy, less water, and hence, you make better use --

THE PRESIDENT: So you make enzymes.

MR. NAGY: We make enzymes. And enzymes is sort of like the key component you need to have when you convert starch or the corn to sugar that you can then make to alcohol or the ethanol. But also, it's got to be the key component when you want to make your switchgrass or your biomass to sugar and then to ethanol.

THE PRESIDENT: So the enzyme begins to break down the raw materials in a particular raw material that will enable us to make more ethanol, is that what you're saying?

MR. NAGY: That is correct.

THE PRESIDENT: Now -- so, is this a -- is this like a huge distillery?

MR. NAGY: Our plant here?

THE PRESIDENT: Yes.

MR. NAGY: Well, you could say what we do here, we use microorganisms, and the way we make these enzymes is by the use of these microorganisms. And you could compare our process to if you brew beer or wine. We take some agriculture raw materials like starch, again, or corn, and then we ferment the insides, basically, like you would ferment wine. The product here is the enzymes that we can then ship off to ethanol plants around in the U.S. And they use it today to break down the starch in corn and make ethanol. So we are a key provider of a key technology to make this happen for you.

THE PRESIDENT: Absolutely. And I presume that one of the bottlenecks to achieving widespread ethanol production is the cost of enzymes. Have you seen any appreciable decline in the cost of enzymes since you have been --

MR. NAGY: Certainly. We have worked with enzymes for many, many years

at Novozymes. We have a 60-year tradition of this, and so we are very,

very good at it. We are the leading edge on all the technologies in all

the markets we are, and therefore we are a company dedicated to

innovation, because innovation, as you talk about, being able to compete

with others, innovation is our tool to do so. And so we reinvest more

than 10 percent -- actually 13 percent of our annual sales back into

R&D.

MR. NAGY: Certainly. We have worked with enzymes for many, many years

at Novozymes. We have a 60-year tradition of this, and so we are very,

very good at it. We are the leading edge on all the technologies in all

the markets we are, and therefore we are a company dedicated to

innovation, because innovation, as you talk about, being able to compete

with others, innovation is our tool to do so. And so we reinvest more

than 10 percent -- actually 13 percent of our annual sales back into

R&D.

The research we do in cellulosic ethanol right now is the biggest research of what we have in the company, where more than a hundred researchers around the globe work on solving the issues ahead of us. What we have been able to do since 2000 until we reported it in 2005, on a grant provided to us from Department of Energy, is to reduce the cost of conversion by a factor of 30.

THE PRESIDENT: I want to repeat, because you actually -- he's talking about your money. (Laughter.) And he said that we gave a grant -- we, the taxpayers of the United States, gave a grant to the researchers of this company, see if they could not reduce the cost of producing the enzymes that would be critical to making ethanol, and this company was able to do so -- reduced the cost by a factor of 30, which I think is a justifiable use of taxpayer's money to see those kinds of results.

MR. NAGY: Thank you.

THE PRESIDENT: You got a lot of Ph.D.s and advanced degrees here?

MR. NAGY: Yes, we do. (Laughter.) We have a few, yes.

THE PRESIDENT: You do?

MR. NAGY: Yes, we do.

THE PRESIDENT: The reason I mention that is that part of remaining a competitive society is to make sure our children get a good education early, so that it is possible to get advanced degrees -- at least a degree beyond high school. If you want a good job in America, you better go on after high school. The jobs in places like this are jobs that require brain power, as much as anything else. And, therefore, the educational system of this state, for example, has been critical in attracting industries such as the company we're talking about here. I mean, I go walking through the halls and shaking hands with people -- we got people on -- doing sophisticated computer programming; we got lab technicians who have got advanced degrees in bioengineering. And my only point is it reminds me of how important higher education is for this country. And I applaud the folks of North Carolina about being on the leading edge of education, and that's why you got companies like here, like this company here, paying pretty good money for jobs, I guess.

MR. NAGY: That's correct. One of the reasons, and what we really enjoy here is also the -- you alluded to the education system here, but it's an integrated system from community colleges through all the levels at university. And there's a number of universities in the state that we also enjoy very close collaboration amongst. Some of them are NC State University, of course.

THE PRESIDENT: Good. Well, Thomas, thanks, buddy. I appreciate it. You handled it well. (Laughter.)

Kevin Wenger. Yes, Kevin, how are you? What do you do?

DR. WENGER: I'm the manager of the R&D group that we have here in North Carolina for ethanol research.

THE PRESIDENT: For this company.

DR. WENGER: For this company, yes. We, about five years ago, decided to invest in a dedicated R&D group for ethanol process development, and we decided to anchor that research group here in North Carolina, because the U.S. is really where the ethanol market has been very strong.

THE PRESIDENT: And you've got a degree in what?

DR. WENGER: I have a degree in chemical engineering, Ph.D. from Colorado State University.

THE PRESIDENT: Good.

DR. WENGER: And I've been here in Novozymes since I finished graduate school in 1994.

THE PRESIDENT: And so in 1994, were you thinking switchgrass into -- (laughter.)

DR. WENGER: I've always been interested in alternative energy and making ethanol. There wasn't so many jobs related to switchgrass in 1994. (Laughter.)

THE PRESIDENT: Well, cellulosic.

DR. WENGER: Yes. But I was always -- I've always been interested in fermentation also, and so Novozymes is a fermentation company and that's how I ended up here.

THE PRESIDENT: Interesting. And so I'd like to quote what he said. Kevin said, "It's going to be a challenge," -- talking about achieving what we're talking about here -- "but if we look at how far we've come in the past five years, we have so much momentum, it shouldn't be that tough."

And the reason I quote a person who knows what he's talking about when it comes to developments necessary to bring the cellulosic ethanol to market, I quote him because I presume in that optimism there's realism.

DR. WENGER: Yes, I'm very optimistic, but also I can see how the 20-in-10 goal is very achievable. If you look at what's happening now, what's been happening with corn ethanol over the last five years and the developments that are coming in terms of implementation of cellulosic, it's really amazing. Things are really starting to happen.

THE PRESIDENT: What he referred to is something I should have talked about earlier, and that is I set a goal of the United States reducing our gasoline consumption by 20 percent over the next 10 years. That's the 20-10 goal. In other words, it is a goal. And I mandated a fuel standard that says we'll be using 35 million gallons of ethanol or alternative fuel over the next 10 years.

Now, the reason I did this is I think it's possible to do it. And the reason I think it's possible to do it is because of people like Kevin telling me it's possible. Remember, I'm the history major. (Laughter.) And so the advances you've seen in five years -- if you're able to take yourself back five years ago to today, it is a noticeable difference, a -- obviously reduced the cost of enzyme, for example, which is an important development.

DR. WENGER: Yes, absolutely, it's a very noticeable difference and in terms of the number of industry players that are really interested in this technology and are also willing to invest in making this technology happen, including Novozymes as an industry player, it's really amazing what we're seeing over the last five years.

THE PRESIDENT: The high price of energy has caused private capital to say that it's going to be impossible for a society like the United States to sustain its use on gasoline. So whether it be Novozymes who is investing, or private sector funds, that money is coming in. They're fueling new research and development. So we've got the government helping, but also you've just got to know that the private sector is very much involved with trying to invent the technologies necessary to take advantage of a society that recognizes it has to diversify away from energy.

And I repeat to you, we're all connected, and so when a Chinese economy grows and their demand for oil goes up, it affects the price that you pay for gasoline. People got to know that. And therefore, it's important for us to continue to advance these kinds of research projects.

I met Dr. Mike in Greeley, Colorado, a year ago.

DR. PACHECO: Golden, Colorado.

THE PRESIDENT: Exactly, Golden, Colorado. How quickly they forget. (Laughter.) I am 60. (Laughter.) Golden, Colorado. Michael, tell them who you work for.

DR. PACHECO: Mr. President, I work for the National Renewable Energy Laboratory. We're the leading laboratory for the Department of Energy in the field of renewable energy. We have a very robust program, as you know, in the field of biofuels, and it's focused right now on cellulosic ethanol.

I agree with Kevin, your 20-in-10 goal is very achievable. In fact, the growth of the corn and the biodiesel industry, which since you signed the Energy Policy Act two years ago, have been growing at over 100 percent per year. Those fuels are going to make a major portion of that 20 percent. But we have to, as you indicated, begin the transition to use a broader base of fuels.

Two years ago we issued a study with USDA, two agencies together, that showed that the U.S. could produce enough raw biomass that's equivalent to about 60 percent of all the oil that we use in the United States. The problem is that most of that biomass is not an easy material to convert. It's not like corn grain. And so our research --

THE PRESIDENT: Explain to people what you're talking about.

DR. PACHECO: Things like forest residues, things like fast-growing trees and switchgrass -- the major constituent in that material is a cellulose fiber, usually accounts for more than half of --

THE PRESIDENT: Do you know what switchgrass is? Tell them what switchgrass is.

DR. PACHECO: Switchgrass is a native grass that grew in the Midwest; it's a grass that grows in relatively poor conditions, it can survive droughts very well.

THE PRESIDENT: Rocky soil and dry. Sounds kind of like parts of Texas, doesn't it? (Laughter.) Imagine, however, if you're able to grow a grass where it's rocky soil and dry that you're able to convert into energy. You're talking about a major change in the lifestyle of your children and my children and their kids. I mean, this is -- anyway, go ahead. (Laughter.)

DR. PACHECO: You're doing very well. (Laughter.)

THE PRESIDENT: I am passionate on the subject. (Laughter and applause.)

DR. PACHECO: But that's a really big part of it, Mr. President, being able to move to those marginal conditions and grow crops in areas where we're not currently growing crops, and then to have those crops that are specifically designed to produce feedstocks that are adapted well for the enzymes that Novozymes is producing can really increase the yield -- that is, how much ethanol we can make from a ton of biomass.

One of the challenges when we started this project between NREL and Novozymes was that no one in the world really felt like enzymes could be a cost-effective technology in producing ethanol from raw material. Today all the leading researchers in the world are working in that area because of the partnerships and because of the progress that Kevin has already talked about.

But we're not there yet. And while I'm optimistic, like Kevin, there's still a lot of hard work left to do, Mr. President. And we have work in the pre-treatment area, we have work still to do in the enzymatic hydrolysis, and we still have research in the fermentation side. And so DOE right now is considering proposals to work with industry in the area of developing fermentation organisms, which is a really important part because the yeast, the bugs today that we use to make ethanol won't work in the future with these new feedstocks. So it's really important that we start this transition.

At NREL we work with all the other national labs. We especially work with Argon National Lab and Pacific Northwest and Idaho and Oakridge. Those are all labs that work together within my center, and we try to coordinate our efforts to utilize all the skills at the national laboratories, because each of the labs brings a unique set of skills to this challenging problem. We also work with a lot of other companies, in addition to Novozymes. And those interactions are equally as important, because one of the things that we're trying to do, Mr. President -- when we talked last year we talked about this -- is to try to develop transitions that grow from existing industries. So instead of replacing the corn ethanol industry, we see cellulosic as evolving from it.

Similarly, we can see how the pulp and paper industry might be able to evolve into bio refineries. Maybe even the massive petroleum refineries can someday evolve to take biomass materials, and you know we're doing some research in that area, as well.

It's really important that we stay on this track, because in the long run, there's no other sustainable source of liquid transportation fuels other than biomass. So we have to succeed at this.

THE PRESIDENT: You know, it's interesting, you're probably wondering whether or not automobiles can be easily converted to use ethanol, and the answer is, absolutely. There's a lot of automobiles in the Midwest that are filling up with 85 percent ethanol, called E85 pumps. It doesn't take much. So one of the barriers to the advent of a lot of ethanol use is not the automobile. It's easy to convert them. As a matter of fact, some of you out there probably have got a car that can use ethanol and you just don't know it -- flex-fuel automobiles, they're called.

Secondly, the production process. Once we figure out what needs to take place internally, it's not that expensive, relative to huge gasoline refineries. What will happen is, when you get a wood chip breakthrough, for example, where it becomes cost effective, you're going to have ethanol production plants all across North Carolina, where the wood chips can be gathered.

One of the reasons we keep talking about costs, it's just real practical. Somebody is not going to fill up their car with ethanol if it costs a lot more than gasoline. The consumer is pretty wise, and they care about the environment, no question about it. But if a person is having to drive back and forth to work, they're going to generally pick the most economically competitive fuel to do that. People want to keep money in their pocket, and therefore, if it costs less using gasoline, they'll use it. So, therefore, that's why we're driving these research dollars, to get the cost of producing ethanol down so it can compete. And it's going to happen, because as that price of oil goes up, the price of gasoline goes up, which makes ethanol more competitive. And one reason -- just so you know -- one reason why there's been such a push, is because when the price of oil went up from early 2001 to where it is today, about $60 a barrel, people saying, we may not be able to sustain this, we better get moving. And that's what's happening.

North Carolina State. Ratna. Welcome. Thank you. You're a doctor of?

DR. SHARMA: Biological engineering.

THE PRESIDENT: Biological engineering. Chemical engineering. Biological engineering. (Laughter.) People should be getting the picture that we've got a lot of smart people working on this project. When you've got Ph.D.s surrounding the President talking about doing what's right, we've got a lot of brain power working on it. And that's where you're going to get your breakthroughs.

So what are you working on?

DR. SHARMA: Mr. President, first of all, I'd like to thank you for your support and interest in the development of these technologies for cellulosic ethanol.

I essentially represent all the research of my colleagues at North Carolina State University and across the country in different universities who have been working in this area of converting residues from the farm, forest, animal operations, possibly even food industry waste to convert it into ethanol and make our country self-reliant and achieve the goal of 20-in-10.

But, as has been mentioned, there are challenges. We have to overcome those, and it's possible we can do that. We do need more investment and funding support, definitely, to speed up this process of achieving this goal in 10 years.

THE PRESIDENT: So what do you think? I mean, how long have you been doing this for?

DR. SHARMA: I've been doing this for about four years.

THE PRESIDENT: Really? So when you got your Ph.D. you never dreamt you'd be thinking about converting wood to oil for fuel. What did you feel?

DR. SHARMA: Well, I was trained as an agricultural engineer, and I grew up on -- on an ag university campus with farms around me. So I always saw residues lying around and plants and stuff. And I got my Ph.D. in food safety engineering where I learned about microorganisms. So then I saw this opportunity, it was like putting together engineering and microbiology, to process something and get value from something that's typically not --

THE PRESIDENT: And there are other people at North Carolina State working with you on this project?

DR. SHARMA: Yes, there are. There are people working on utilizing forest residues, wood chips for converting to ethanol. There are people working on different ag residues -- sweet potatoes, which is a starch, base feedstock, people working on biodiesel, from -- again, from agricultural resources.

So there are a lot of people working on overcoming the challenges of pretreatment and converting the carbohydrates into sugars and then eventually fermenting it into ethanol. And my focus has been more on ag residues, like cotton stalks, hays and straws, which would typically not be --

THE PRESIDENT: Cotton stalks, pretty interesting, isn't it?

DR. SHARMA: They are.

THE PRESIDENT: They now get plowed up in the ground. Your idea is to get them so they can end up in somebody's automobile, not in the ground.

DR. SHARMA: Exactly. So there is a lot of potential. And like switchgrass, which grows in marginal lands. And we have, like you mentioned, a big swine industry in North Carolina. So the advantage is we could possibly put the two together, use animal waste as a nutrient source to grow the switchgrass and then convert it into ethanol so you're getting energy from waste.

THE PRESIDENT: So are people pretty upbeat about it? People --

DR. SHARMA: Well, people who are aware and looking forward to switching from fossil fuels to renewable energy, yes, they are.

THE PRESIDENT: Yes, pretty good.

DR. SHARMA: And they feel it's achievable. We can do it. We just need to work a little harder on that.

THE PRESIDENT: Yes. A little more money and a little harder. (Laughter.) Talk to my man, Michael. He's the guy distributing some of the money. (Laughter.) Well, good. Thanks, Doc. Thanks for joining us. I'm sure proud you're here. NC State is a fine, fine institution. I know you're proud to work there.

DR. SHARMA: Yes, I am, definitely.

THE PRESIDENT: Ryan, where are you from?

MR. ADOLPHSON: From the University of Georgia in Athens, Georgia.

THE PRESIDENT: A bold man to come here to North Carolina. (Laughter.) A great school, by the way. What do you do?

MR. ADOLPHSON: I'm with the university's -- I'm in charge of our bio -- our pilot facilities that are looking into early transitioning some of this technology from the bench out to industry, looking at really the wide, or broad spectrum of this concept of biomass to energy that includes fuels and includes electrical and different bio products, and really running the gamut of this whole type of industry. And we have a pretty large research facility looking into this at all levels.

THE PRESIDENT: In Athens?

MR. ADOLPHSON: In Athens, yes -- bio-refining and carbon cycling center that we've recently started in the last two years.

THE PRESIDENT: What is a bio -- what is a carbon recycling center?

MR. ADOLPHSON: Carbon cycling.

THE PRESIDENT: Carbon cycling.

MR. ADOLPHSON: Right. So we're looking into the concept of a bio refinery, which Mike mentioned, and really taking a little bit bigger picture view, stepping back, not looking only at ethanol, but counting ethanol as a significant piece to the puzzle, but looking at all the other products that can be generated from bio mass. You know, similar to a petroleum refinery that takes a barrel of crude and doesn't just make diesel and gasoline, but 50, 60 other products out of that.

So we're looking at our wood chips as that barrel of crude, taking that, and turning it into a larger profit stream than just a single product, and we believe that's going to drive the economics --

THE PRESIDENT: What other products?

MR. ADOLPHSON: There's a whole host of products. You know, the char, the stuff that's in a thermochemical process, instead of a biological process, or the sugar platform. The Department of Energy really breaks up when they talk about our production of ethanol in two pathways: one is thermochemical and the other is our fermentation, or our sugar platform that we've kind of been talking about now.

The thermochemical platform allows us to take all these different biomass streams, treat them with heat in a certain way, release all of the energy from those, and we can capture that, turn that into our product.

So one product we have left is the carbon that's left over. We're able to look at that as a soil amendment and take that carbon without releasing it into the atmosphere and put it back into the ground. And then we have everything that comes out of that biomass that we can turn into ethanol and we can turn into specialty chemicals for our chemical industry as precursors to things like nutraceuticals, pharmaceuticals, and then we have the gas that comes off that could be maybe cleaned up and used as a pipeline-quality gas, like natural gas, to heat homes.

THE PRESIDENT: All from one big pile of wood chips?

MR. ADOLPHSON: All from one big pile of wood chips, right. You know, we're at a very unique place --

THE PRESIDENT: You've got to dream big in order to be able to get it done. (Laughter.) That's good.

MR. ADOLPHSON: We are at a unique place right now, and the technology is there.

THE PRESIDENT: Pretty interesting, isn't it? It's -- I'm not so sure if they'd believe me in the coffee shop in Crawford if I told him what he just told me. (Laughter.) But it's possible.

MR. ADOLPHSON: It is, right. I like to say, we're not there yet, but we can see it from here.

THE PRESIDENT: You can, yes.

MR. ADOLPHSON: We've got two -- on the ground in the next 18 months in Georgia, we've got a biorefinery taking wood chips to ethanol, we've got a traditional corn ethanol plant going in, we've got two, what we call, integrated biorefineries that are going to be pulling mostly -- we have 24 million acres of commercial forest in Georgia. So that's a big priority for us. And the pulp and paper industry has been -- has been going other places.

THE PRESIDENT: Are they investing?

MR. ADOLPHSON: The industry itself?

THE PRESIDENT: Yes.

MR. ADOLPHSON: The part of the pulp and paper industry, that is the growers, the land owners, are very interested in finding a market for their wood so they can get a higher price for it. I think the paper mills might be less interested in paying a higher price for their feed stock than the growers are. But yes, they're definitely investing. The University and Governor Purdue has sent a mandate out for us to really invest in public/private partnerships. So we can take the public money, and he likes to say he wants to see industry with skin in the game, who is able to put money and people involved in this effort.

And so we're -- we've created a facility. We can locate industry on campus with us, so that when we do develop a technology, this technology transfer from academia to industry is seamless. We're excited about that because guys like us who are in academia or government, we can provide money and resources, but it's going to be the market that will have to pick it up and take it to get it into the consumers.

THE PRESIDENT: Absolutely, yes. That's pretty interesting, isn't it? Thanks for coming. I'm glad you came over.

MR. ADOLPHSON: Thank you, Mr. President. We're excited to be here. Great opportunity.

THE PRESIDENT: And we're going to end up with Terry. Terry Ruse.

MR. RUSE: All of the Ph.D.s around the table. I don't have one of those, but I --

THE PRESIDENT: I'm glad to join you. (Laughter.)

MR. RUSE: I'm happy to report to you that the ethanol industry is alive and well and up and taking nourishment.

THE PRESIDENT: So what do you do?

MR. RUSE: I am the Chief Operating Officer for Agri-Ethanol. That's a privately-held ethanol company in Raleigh.

THE PRESIDENT: And what do you -- so what --

MR. RUSE: We are developing -- our strategic plan is to develop 10, 108-million-gallon-a-year ethanol plants in the --

THE PRESIDENT: So you're going to be the manufacturer?

MR. RUSE: We are going to be the manufacturer. Thanks to the vision of Dave Brady and the guys that own Agri-Ethanol, I've been able to develop a really flexible project in that we have a design to start out as a corn plant to process corn. We were building 11,000 foot of track -- big loop track to be able to bring corn in by rail and take ethanol back out.

In the center of that loop track, we've engineered the ability to handle wood chips. We've got all that in place. We have a CO2 company that will process the CO2, anything -- any of the CO2 that doesn't go to that direction to make food grade liquid carbon dioxide will be directed into hydroponic gardening or into growing algae to support an adjacent biodiesel plant. Now we have the real estate to put one of those on.

THE PRESIDENT: So you intend to buy the enzymes from this company to run in your plant --

MR. RUSE: We have this -- as a matter of fact, we have offered them the opportunity to establish a field research laboratory on our site so that they don't have to go long distances to get their people and do really ground work --

THE PRESIDENT: Where is this thing?

MR. RUSE: It's in Aurora, North Carolina. It's the first one. It's about 160 miles east of Raleigh.

THE PRESIDENT: And when will you -- are you building it now?

MR. RUSE: We are ready to break ground. One of the interesting facts about that is that we have the site completely controlled. We have it totally permitted. But in trying to talk to the financial people about putting money, I've spent two years trying to convince them that it makes sense to build an ethanol plant in North Carolina as much as it does one in Iowa. And we haven't gotten that done. And so --

THE PRESIDENT: See, you can't build a plant far away from the raw material. That's the interesting thing about this industry. What he's basically saying is, is that investors think you have to be in the middle of a corn field. Really. And that's why there's a lot of plants being built in the Midwest because there's a lot of corn in the Midwest.

MR. RUSE: But because of the fact we're closer to the population density centers for the ethanol, and the animals that we have in North Carolina, we can prove that our plant is as competitive as the plant in Iowa.

THE PRESIDENT: You can't have a centralized plant and ship your ethanol long distances, either. The production needs to be close to the raw material and the users, is what you're saying. And the economics.

MR. RUSE: That's exactly correct. And this -- each one of these plants will produce about 400,000 tons a year of highly digestible, high protein feed to help the hog farmers, that you alluded to, get over their heart pain of --

THE PRESIDENT: High corn.

MR. RUSE: Of high corn. And coming from the farm, the thing that I understand most is the resiliency of the American farmer. You give him a good price for the corn, and he will grow the corn. And I think that when the March planning report comes out, you'll see closer to 13 billion or 13.5 billion bushel corn market, and 90 million acres planted than what we've seen in the past.

And so all of the price concerns from the animal growers and from the Wall Streeters will be --

THE PRESIDENT: Will be eased somewhat. That's right. He's right. It's amazing how the market responds.

MR. RUSE: And the one last piece of our project is that we intend to build a green truck stop on each one of these sites that sells biodiesel, sell E10 and E85.

THE PRESIDENT: That would be good. E10 is ethanol -- 10 percent ethanol.

MR. RUSE: Ten percent ethanol and 85 percent ethanol and then biodiesel.

THE PRESIDENT: The purpose was to give everybody a sense of where a lot of smart people and good capital are moving. Smart people are here working on some amazing technologies that -- you know, that I believe 10 years from now people will say, gosh, it's interesting that they were worried about this particular technology coming to fruition, because it's coming to fruition. And the role of the government is to stimulate thought and investment and set goals. And we set a big goal, really have -- reduction of gasoline by 20 percent over the next 10 years.

I wouldn't have done that if I didn't think it was achievable. Part of it is to change our CAFE standards on automobiles, which will encourage conservation. The other part is to change the fuel -- fuel mix across America.

And this is a coming time. It really is. And I want to thank those of you who are on the front line of changing it. It must be exciting for you to be able to work on something so novel and so encouraging and so important for our country.

I thank the good folks at this important company for letting me come by to say hello. I ask for God's blessings on the United States of America. Thank you. (Applause.)

END 12:54 P.M. EST